Comprehensive On-Site Service Calibration Solutions

Knowing the demand of today's manufacturing schedules and the disruption to work flow caused by gages being sent to outside sources for calibration, QCS offers complete on-site services for calibration and repair of most hand tools, optical comparators, hardness testers (including Rockwell and Micro), Torque wrenches, Microscopes, Spring Testers, Scales, High Accuracy Bench Micrometer, Surface Plate Calibration and Resurfacing and Electronic Test and Measurement Equipment and more.

Field Service Provides Efficiency

Equipped with complete master reference standards, our technicians deliver on-site calibrations and adjustments for micrometers, indicators, and most other various Hand Tool Gages. QCS On-Site Calibration service helps eliminate disruptions to the customers manufacturing process and work flow.

Industry-Experienced Technicians

Benefit from the expertise of Quality Calibration Service technicians with many years of experience in the industry. Our team undergoes thorough training in all facets of field service work, ensuring precision and reliability.

Uncompromising Calibration Standards

Most gages listed can be calibrated on site.

See Field Service Section

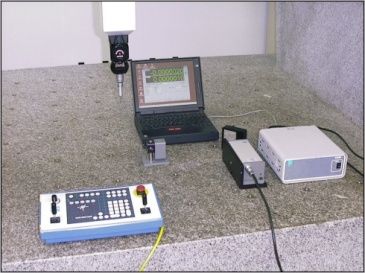

Efficient Electronic Data Collection

Our technicians utilize a portable computer system for electronic data collection during calibrations, eliminating errors associated with handwritten documents. This efficiency ensures accuracy in calibration records.

Equipment Repair Services

Our technicians ensure proper repair and calibration at our main facility for instruments requiring repairs beyond on-site capabilities. All Gage Repairs are quoted in advance including other cost-effective solutions including new gage replacements.

Mechanical Field Service

Quality Calibration Service can calibrate and repair most types of electro/mechanical test and inspection equipment, including but not limited to coordinate measuring machines, optical comparators, hardness testers, roundness testers, high accuracy bench micrometers, surface analyzers, bench centers, laser alignment of machine tools and measuring equipment.

Electronics Field Service

Quality Calibration Service has several electronic multiproduct calibrators and can perform field service calibration on most electronic test and measurement equipment types. All calibration includes long-form certification with before and after readings and direct traceability to the NIST.

Precision CMM Calibration Services

Discover the precision of A2LA-accredited (ISO/IEC Guide 25) CMM calibration at Quality Calibration Service (QCS). Our calibration strictly follows ANSI B89.4.1 standards, meticulously evaluating repeatability and linear, volumetric, and bi-directional errors. For repeatability tests, we employ the master sphere, ensuring accuracy. Linearity tests are executed with a step master or laser system, delivering precise results. Volumetric tests utilize a ball bar for comprehensive assessments and bi-directional error using gage blocks.

Quality Calibration Service offers a comprehensive suite of services: calibration, adjustment, repair maintenance, laser characterization, relocation, and retrofit. We provide a detailed long-form certification adhering to manufacturer specifications with every calibration. This comprehensive report ensures accuracy and transparency in our calibration services by including before and after data and insightful graphs.

Surface Plates Field Service

Leverage the highly accurate Federal Electronic Level System at Quality Calibration Service for comprehensive calibration, lapping, and resurfacing of granite plates, squares, and parallels.

Precision Measurements with Electronic Levels

Our electronic levels precisely measure deviations in the right-angle relationship between a horizontal surface and the earth's gravitational force. This angular or linear analysis highlights changes over time, ensuring measurement accuracy.

Mandated Quality Standards

Quality Calibration Service mandates using a Repeat-O-Meter and a Rahn Planekator to ensure overall flatness and repeatability accuracy, complying with Federal Specification GGG-P-463c paragraph 4.5.5.

Profiling for Accuracy

Generate a precise three-dimensional surface profile using a straight edge and electronic levels. We record and download readings into our portable computer systems and analyze them with a profiling program designed for this application.

Comprehensive Certification of Calibration

Receive a long-form certificate of calibration traceable to NIST and Fed Spec GGG-P-463c. Our service provides a complete 3-D profile of your plate, including all generated data about overall flatness and accuracy, furnished promptly after the job and at billing.

Resurfacing Capabilities

Quality Calibration Service offers lapping and reconditioning for plates with excessive wear or pitting. Grinding services are available for steel or iron plates. We inspect all plates before resurfacing to ensure proper load stability capability, providing long-form certification at billing.

Contact our experienced team today at

414-256-8900 for excellence in metrology.